Overview

A leading logistics and manufacturing enterprise partnered with Banao Technologies to build an end-to-end Supply Chain Intelligence Platform. The platform enables real-time data aggregation, predictive insights, and AI-driven demand forecasting—empowering businesses to make faster, smarter, and more resilient supply chain decisions.

Industry

Logistics & ManufacturingBusiness type

Enterprise Supply Chain Management

Build your idea

Consult our expertsImpact After Launch

Post-deployment, the platform provided end-to-end visibility across global logistics operations. Predictive insights helped reduce shipment delays and inventory risks, while advanced dashboards improved decision-making accuracy for executives and operations managers.

Key results achieved after deployment

0+

real-time data points processed daily from supply chain networks,

0+

reduction in inventory holding costs across global warehouses, and

0%

improvement in forecasting accuracy across operations.

Challenge

The client struggled with fragmented data across logistics partners, leading to poor visibility and inconsistent forecasting. Manual tracking of shipments and lack of predictive insights caused delays, inefficiencies, and lost revenue opportunities.

Our Solution

Banao Technologies built an AI-powered platform that unified data from ERP, IoT, and logistics APIs into a single cloud-based dashboard. The system used machine learning algorithms for demand prediction, anomaly detection, and real-time shipment visibility. We also developed custom analytics dashboards for role-based decision support.

Features Implemented:

- Real-time data integration from multiple logistics and ERP sources

- Predictive analytics for demand forecasting and inventory optimization

- AI-driven anomaly detection and alerting

- Interactive data visualization dashboards with KPI tracking

- Cloud-native architecture ensuring scalability and security

Key Features Implemented

A next-generation AI and analytics solution for global supply chain transparency, risk management, and automation.

Predictive Demand Forecasting

Machine learning models analyze historical sales, logistics, and market trends to predict future demand accurately.

Real-Time Visibility Dashboard

Consolidates data from sensors, ERP systems, and APIs into a single pane of glass for unified monitoring.

Automated Anomaly Detection

Detects and alerts users about shipment delays, route deviations, or data inconsistencies instantly.

Smart KPI Insights

Custom dashboards highlight key metrics like fulfillment rate, lead time, and cost per shipment for better decisions.

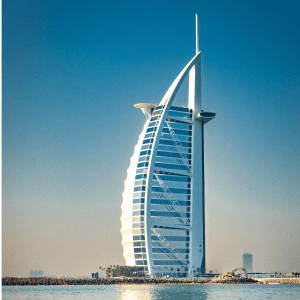

Where we're located

Frequently Asked Questions

How did the platform improve supply chain transparency?

By aggregating real-time data from multiple sources, it enabled unified tracking and visibility across vendors and geographies.

Did the system support predictive analytics?

Yes, machine learning models provided accurate demand forecasts and automated anomaly alerts to prevent operational risks.

How much efficiency improvement was achieved?

The platform achieved a 48% improvement in forecasting accuracy and reduced logistics response time by nearly 40%.

Is the system scalable for multiple partners?

Yes, the cloud-based architecture supports easy integration with new data sources, APIs, and enterprise systems.