Overview

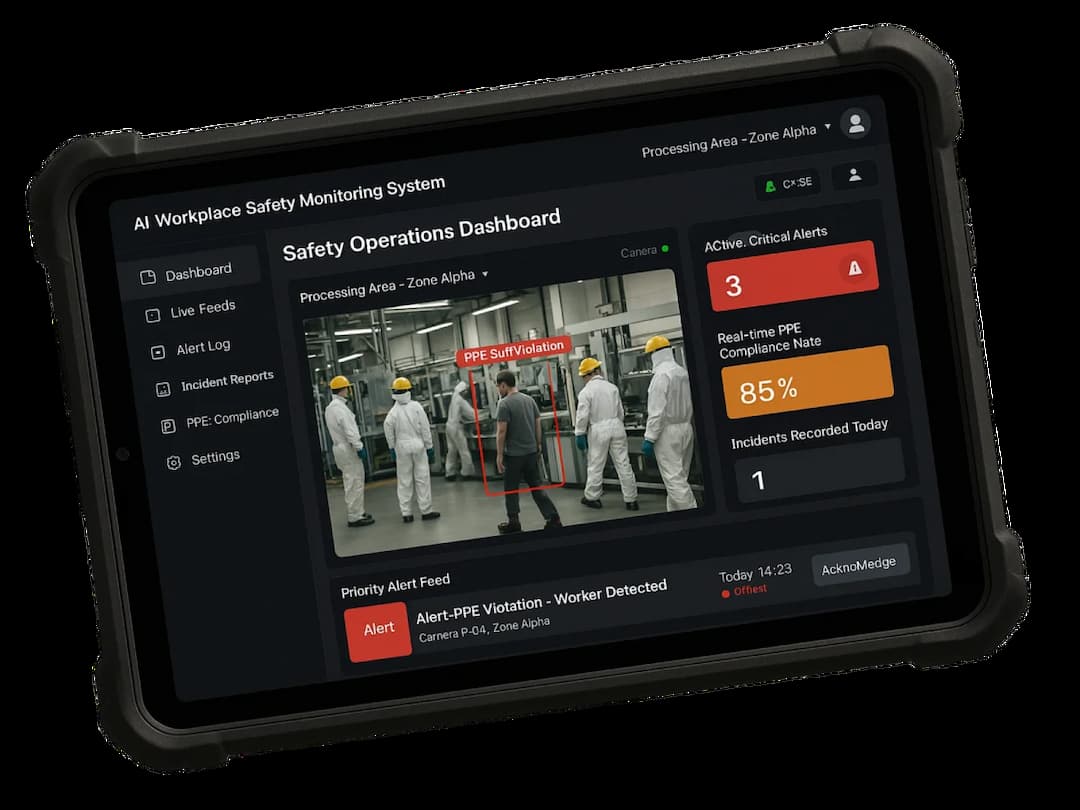

A large industrial client partnered with Banao Technologies to deploy an AI and edge-computing based safety platform. The solution uses computer vision to detect personal protective equipment (PPE) violations, monitor unauthorized zone access, and flag safety risks in real time. This proactive approach has significantly reduced workplace accidents and enhanced compliance with safety regulations.

Industry

Industrial Safety / ManufacturingBusiness type

Enterprise / Manufacturing Plant

Build your idea

Consult our expertsImpact After Launch

The implemented solution empowered the client to proactively manage safety incidents, reduce manual inspection efforts, and create smarter alerts for non-compliance. Real-time alerts and AI analytics elevated the safety culture across the site.

Key results achieved after deployment

0+

safety alerts processed automatically,

0+

manual inspections eliminated per month, and

0%

improvement in PPE compliance rate.

Challenge

The client’s safety team relied heavily on manual visual inspections, lacked real-time zone monitoring, and had minimal automation for PPE compliance checks. The process was reactive rather than proactive.

Our Solution

We designed and deployed a computer vision system at the edge which monitors video feeds for PPE violations and unauthorized zone access. We integrated the system with the plant’s safety dashboard, created real-time alerts, and built analytics to measure compliance trends.

Features Implemented:

- PPE detection using computer vision (helmets, vests, gloves)

- Unauthorized zone access detection & geo-fencing

- Edge-based analytics for low-latency alerts

- Integration with safety dashboard and workflow automation

Key Features Implemented

A comprehensive platform combining AI, edge-computing, zone monitoring and workflow automation to enhance workplace safety.

Real-Time PPE Violation Detection

Automatically identifies missing PPE items in live video streams and triggers alerts for immediate action.

Geo-Fenced Safety Zones

Monitors restricted areas and flags unauthorized access to ensure compliance with safety protocols.

Edge Analytics for Low-Latency Alerts

Processes data on-site to deliver near-instant alerts and reduce dependence on cloud latency.

Safety Dashboard & Automation

Centralizes safety metrics, incident logs and integrates with workflows to escalate issues seamlessly.

Where we're located

Frequently Asked Questions

What types of PPE can the system detect?

The solution can be configured to detect helmets, safety vests, gloves, eyewear and other client-specific equipment using vision models.

Does the system work in adverse lighting or multiple cameras?

Yes — we deploy models optimized for varying lighting conditions and multi-camera setups to ensure coverage across the facility.

How does the edge deployment benefit the client?

Edge deployment greatly reduces latency for alerts and ensures that safety monitoring continues even if the network connectivity to cloud is interrupted.

What measurable improvements did the client see?

The client reported thousands of safety alerts processed automatically, a significant reduction in manual inspections and a measurable uptick in PPE compliance over time (exact numbers to be verified).