AI for Manufacturing Development

Transform Manufacturing with AI-Powered Industry 4.0 Solutions

Revolutionize manufacturing with intelligent automation, predictive maintenance, and smart factory solutions. Banao's AI manufacturing services enhance production efficiency, reduce downtime, and enable Industry 4.0 transformation for modern manufacturers.

Choose AI to Revolutionize California Manufacturing

Why rely on reactive, legacy industrial processes when California’s manufacturing, logistics, energy, and advanced materials clusters demand predictive, connected, data-driven performance? AI here enables condition-based maintenance, adaptive quality, digital twins, orchestrated robotics, energy optimization, and resilient supply synchronization— powering Industry 4.0 outcomes across the Emirate.

AI for Manufacturing Development California

Start your California AI Manufacturing journey here

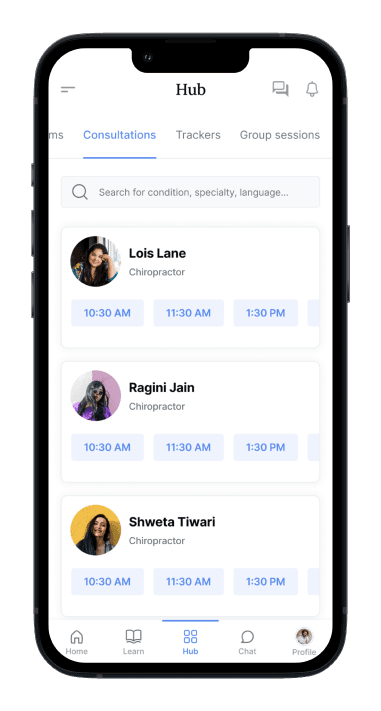

Predictive Maintenance & Monitoring (CBM)

Develop AI systems for sensor fusion equipment health scoring, early anomaly detection, predictive maintenance scheduling, and downtime prevention across California industrial assets.

Quality Control & Inspection

Build intelligent quality control systems: computer vision defect detection, surface anomaly classification, inline inspection dashboards, and continuous yield analytics.

Smart Factory Automation

Create AI solutions for production flow optimization, robotics coordination, autonomous workflow routing, and adaptive takt time balancing.

Supply Chain & Demand Forecasting

Implement AI systems for multi-tier supply visibility, probabilistic demand prediction, inventory right‑sizing, and logistics & spare parts optimization.

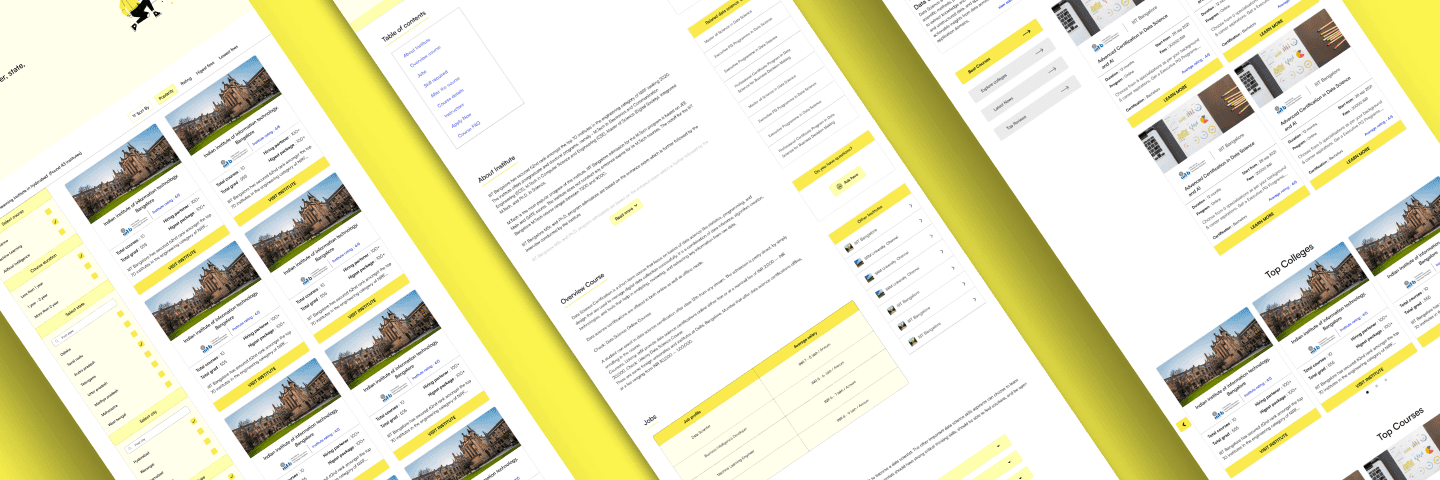

Recent Work

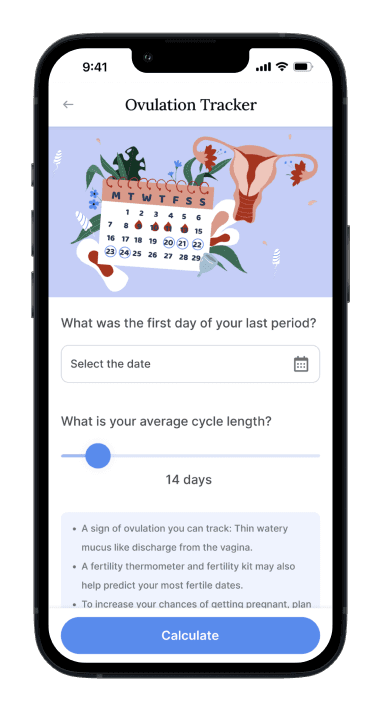

AI Development | Mobile App Development

INDUSTRIAL OEE ANALYTICS

AI-driven platform aggregating machine telemetry & PLC data to deliver real-time OEE dashboards, predictive failure signals, and maintenance scheduling optimization for reduced unplanned downtime.

FACTORY DIGITAL TWIN

A scalable digital twin environment simulating production line throughput, energy usage, and bottleneck scenarios to de-risk layout changes and optimize cycle time before real-world implementation.

VISION QUALITY SUITE

Computer vision defect detection & classification platform reducing false negatives and improving first-pass yield through edge inference and active learning retraining loops.

Our California AI Manufacturing Development Process

Requirement Analysis & Workflow Mapping

We analyze California manufacturing processes, shop floor telemetry, machine states, and supply chain constraints to architect scalable Industry 4.0 AI solutions.

AI Model Development

We build ML models for predictive maintenance (anomaly & remaining useful life), vision quality detection, demand forecasting, throughput optimization, and robotics coordination.

Simulation & Digital Twin Testing

We validate solutions in digital twin + simulation sandboxes for accuracy, scalability, safety, and controlled rollout readiness.

Data Security & Compliance

We implement AI anomaly detection, secure IoT onboarding, encrypted data pipelines, and compliance-aligned governance frameworks to safeguard industrial data.

Deployment & IoT Integration

Seamless deployment integrating MES, ERP, historians, and IoT-enabled assets— unlocking unified real-time AI telemetry & insights.

Continuous Optimization & Monitoring

Continuous improvement: model drift monitoring, retraining pipelines, KPI dashboards (OEE, yield, MTBF), and proactive root cause analytics.

See what our manufacturing clients say...

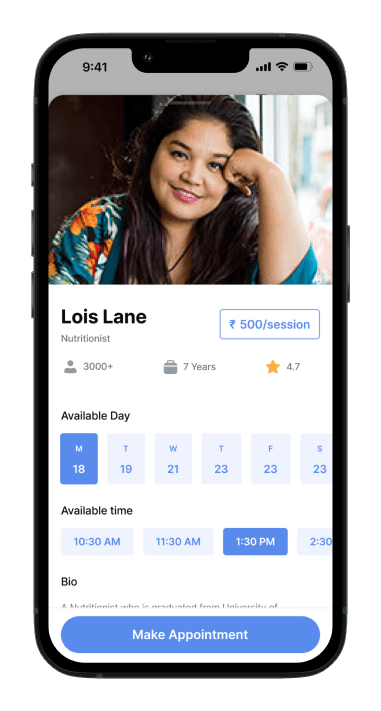

Jabez Zinabu

CEO, LeapifyTalk

RaviKant

CEO and Co-founder, Happimynd

Their diligence and punctuality is enviable!

Banao did a fantastic job in every way. They helped revamp the UI of our website as per our expectations. They were always on schedule when it came to delivering. We're not sure how they accomplish it, but the results are stunning. Their responsiveness and customer service are exceptional, and they are really appreciated.

Where we're located

Let's Build Something Great Together. 🤝

Here is what you will get for submitting your contact details.

45 minutes of free consultation

A strict non-disclosure agreement

Free market & competitive analysis

Suggestions on revenue models & planning

Detailed feature list document

No obligation proposal

Action plan to kick start your project

Frequently asked questions

How is AI transforming California manufacturing?

AI unlocks predictive maintenance, real-time vision inspection, robotics coordination, resilient supply chains, digital twins, energy optimization, and data-driven throughput enhancement across California industrial facilities.

What is Industry 4.0 in the California context?

Industry 4.0 in California converges AI, IoT, robotics, data platforms, and digital twins— enabling autonomous decision loops, predictive insights, and flexible production aligned with diversification strategies.

Can AI reduce downtime in regional plants?

Yes— condition-based maintenance models surface early degradation patterns, enabling planned interventions that reduce unplanned stoppages and spare parts waste.

Do you build AI-powered quality control & vision systems?

Absolutely— we deliver edge & cloud vision pipelines for defect detection, dimensional analysis, surface inspection, and continuous yield analytics.

Can AI integrate with existing MES/ERP/SCADA?

Yes— we integrate via APIs, OPC-UA connectors, historians, and event streams; layering analytics without disrupting critical control systems.

How secure are AI manufacturing deployments?

We implement encrypted data pipelines, network segmentation, secure device onboarding, anomaly detection, and governance frameworks protecting operational & IP data.

Do you offer digital twin simulation for California plants?

Yes— we build scalable digital twins to model line flow, capacity scenarios, energy usage, and layout experiments before physical change.

What measurable benefits can local manufacturers expect?

Expect OEE improvement, reduced downtime, higher first-pass yield, optimized inventory, lower energy intensity, accelerated root cause analysis, and safer workplaces.